Testing Service for SunPower Maxeon Solar Cells

Have the True Efficiency of Your Maxeon Solar Cells Measured!

Purchased SunPower Maxeon cells but unsure about the supplier's specs? Advertised efficiency isn’t always accurate. I offer precise testing of your 125mm x 125mm solar cell samples, measuring their efficiency with 0.2% accuracy.

The cost for measuring 3 samples is $40 if the cells do not need to be returned, you can contact me here.

Efficiency testing service for SunPower Maxeon solar cells

Efficiency testing service for SunPower Maxeon solar cells

An example of a test of Maxeon 3 C60 25.4% solar cells

Here is an example of an efficiency measurement of five samples from a package of 150 Maxeon 3 C60 25.4% solar cells. To determine the efficiency, the cells were compared to other Maxeon solar cells of which the efficiency is known. The measurements confirmed that the average efficiency of the samples is indeed 25.4%. The variation between cells is about 1.5%. Here are some graphs:

Sunpower Maxeon solar sell I-V curve

Sunpower Maxeon solar sell I-V curve

Maxeon solar sell 1380mW

Maxeon solar sell 1380mW Maxeon solar sell 1396mW

Maxeon solar sell 1396mW Maxeon solar sell 1421mW

Maxeon solar sell 1421mW

Reproducibility

The reproducibility of the solar cell testing device is 0.2%. This is achieved by compensating for temperature and light intensity variations. The light intensity of the testing light source is 1/3 of that of the sun. Thanks to the high reproducibility and resolution, we can also measure accurate:

- Solar cell degradation

Determining the efficiency loss over extended periods, such as 3 months in outdoor conditions. - Impact of encapsulation

Determining the efficiency loss caused by encapsulation.

The hystory of the project

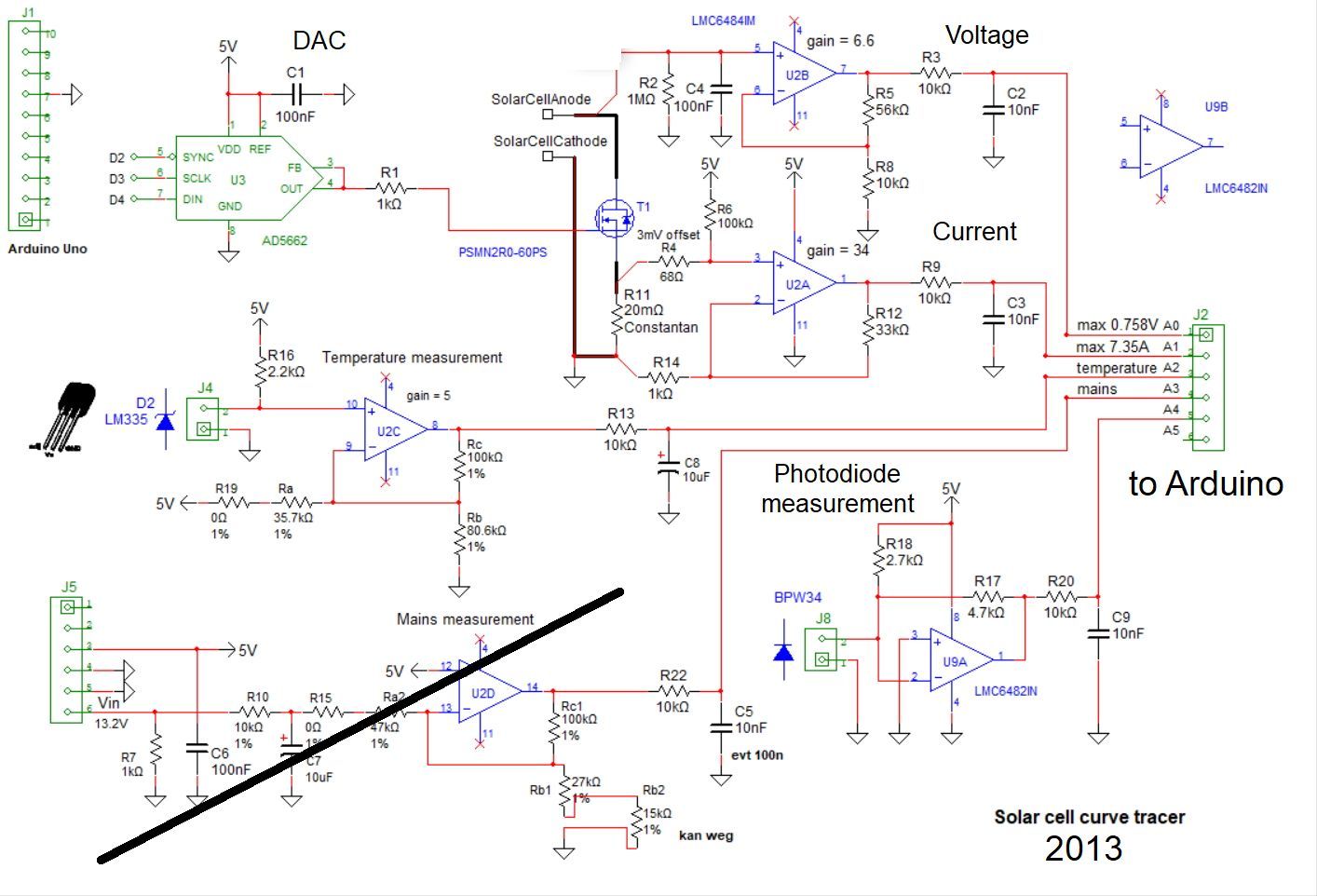

In 2013, I started with my Maxun One solar bike project. For the development of very lightweight solar cell encapsulation materials, I needed to measure the wear due to atmospheric influence. This requires a measurement system with high long-term reproducibility.