Lipo / LiFePO4 ebike battery information

- E-bike batteries are not allowed on an airplane

- Don’t charge to 100%

- Common battery types for ebikes

- Chemistries

- LiFePO4 batteries

- Other Li-ion batteries

- Hybrid supercapacitor battery

- LiFePO4 battery issues

- How to store lithium-ion batteries

- Determining the number battery cells

- Battery internal resistance loss

- Measuring battery internal resistance

- Reviving over-discharged Li-ion batteries

- The history of A123

- Safe charging and storing lithium-ion batteries

- Comprehensive lithium-ion battery test

- Battery links

E-bike batteries are not allowed on an airplane

There is a solution: dividing a battery into smaller packages.

Grin Technologies sells e-bike batteries that are allowed in aircraft luggage.

Don’t charge to 100%

This article explains why, in order to extend battery life, you shouldn't charge to 100%: How to make a lithium battery last, or…kill it, if you like.

Common battery types for ebikes

Batteries for e-bikes can be broadly divided into two types, lithium and LiFePO4. The latter is also lithium but has a lower cell voltage and a very long life. Batteries for e-bikes can be broadly divided into two types, lithium and LiFePO4. The latter is also lithium but has a lower cell voltage and a very long life. The voltage of lithium cells varies considerably during discharge and the nominal voltage is therefore stated with 3.6V or 3.7V.

| Lithium [V] | LiFePO4 [V] | |

| Nominal voltage | 3.7 | 3.3 |

| Charge cut-off voltage | 4.2 | 3.65 |

| Number cells in series for "36V" | 10 | 12 |

| Battery "36V" | 37 | 39.6 |

| Battery charge cut-off voltage | 42 | 43.8 |

Chemistries

Commonly, e-bikes use lithium ion batteries which are available in different chemistries: LiCoO2, LiNiO2, Li-NiCoMn, LiFePO4 etc. LiFePO4 batteries have some advantages: longer cycle life and fast charge capability. The disadvantage is the lower energy density [Wh/kg], but note that the energy density of other lithium ion batteries degrade drastically after some years of usage.

LiFePO4 batteries

A123 ANR26650

Note that I built this battery in 2014 so higher capacity batteries are available in the meantime...

I prefer LiFePO4 battery cells ANR26650 from manufacturer A123. This battery offer high charge rates of 15 minutes, which allow fast charging on the go. There are more LiFePO4 manufacturers, but they differ in quality. Not just the LiFePO4 technology is the key to success, but its patented method in nanotechnology. LiFePO4, like any other multi cell lithium battery needs a BMS, which protects cells from over discharge and over charge. Also a balancer is required which usually combined with the protection circuit.

Here are some figures of the A123 LiFePO4 battery cell ANR26650:

- Battery cells old: 3.3V, 2.3Ah, 7.6Wh, 70g, specific energy: 108Wh/kg

- Battery cells new: 3.3V, 2.5Ah, 8.3Wh, 76g, specific energy: 108Wh/kg

- Recommended fast charge current 10A to 3.6V CCCV, 15 min

- Cycle life at 10C discharge >1000 cycles

- Self-discharge < 2% / month

Chinese LiFePO4 battery 36V / 10Ah

Note that I built this battery in 2014 so higher capacity batteries are available in the meantime...

| Battery | |

| Configuration | |

| Charge cut-off voltage | |

| Discharge cut-off voltage | |

| Measured battery capacity at 5.5A | 398Wh |

| Measured specific energy at 5.5A | |

| Battery cells weight | |

| Total weight | 3.68kg |

| Battery holder weight | 0.36kg |

Other Li-ion batteries

Panasonic CGR18650CG Li-NiCoMn battery 36V / 9Ah

| Battery cells | |

| Rated capacity | 3.6V / 2.25Ah |

| Weight | 44g |

| Rated specific energy | 184Wh/kg |

| Max. charge current | 1C |

| Cycle life at 1C discharge | 600 cycles |

| Battery | |

| Configuration | 10S4P |

| Charge cut-off voltage | 42.5V |

| Discharge cut-off voltage | 30V |

| Measured battery capacity at 5.5A | 308Wh / 7.7Wh per cell |

| Measured specific energy at 5.5A | 175Wh/kg |

| Battery cells weight | 1.76kg |

| Total weight | 2.85kg |

| Battery holder weight | 0.31kg |

LiNiCoAl Lithium Nickel Cobalt Aluminum

This information is out of date, who can make an update?

The highest specific energy of 265Wh/kg can be obtained with the new lithium ion battery chemistry LiNiCoAl from Panasonic and Samsung

| Battery cells | |

| Rated capacity | 3.6V / 3.4Ah |

| Weight | 46g |

| Rated specific energy | 265Wh/kg |

| Max. charge current | 0.7C |

| Cycle life at 1C discharge | |

| Battery | |

| Configuration | 10S3P |

| Charge cut-off voltage | |

| Discharge cut-off voltage | |

| Measured battery capacity at 5.5A | |

| Measured specific energy at 5.5A | 224Wh/kg |

| Battery cells weight | 1.38kg |

| Total weight | |

Fast charge Lipo batteries

Standard Lipo batteries have a low maximum charge current of about 0.2C, but Lipo batteries for model aircraft allow higher charge and discharge currents. Some Lipo batteries have a maximum charge rate of 10C.

ZIPPY Compact 5000mAh 10S 25C Lipo Pack

Specific energy: 5A * 37V / 1.161kg = 160Wh/kg

Max. charge rate 5C.

Note that Lipo batteries are not intrinsically safe, there is a risk of explosion or fire.

Lipo battery, charge rate 5C, specific energy 160Wh/kg

Lipo battery, charge rate 5C, specific energy 160Wh/kg

Hybrid supercapacitor battery

A hybrid battery contains batteries of different technologies. In this way, the hybrid battery can have better properties than the individual batteries. An example is the combination of ultracapacitors and lithium-ion batteries. The ultracapacitor withstands high peak current in contrast to the lithium-ion battery, so the combination has a higher lifetime.

LiFePO4 battery issues

LiFePO4 battery energy storage efficiency versus voltage

When the battery efficiency is 100%, the stored energy is U * I * t. The battery efficiency however varies as function of the voltage. Between 3.0V and 3.4V the efficiency is high; here most of the energy is stored. At the end of the charging cycle, not only the voltage rises rapidly but the battery efficiency is very low too. In other words, there is less energy stored in the battery between 3.6V and 4V.

The evidence of the limited energy storage above 3.6V is that after charging, the voltage drops quickly without load. See the charge curve.

LiFePO4 charge curve

LiFePO4 batteries overcharge tolerance

Usually it is recommended that LiFePO4 batteries should be charged until the voltage reaches 3.6V. They can however be overcharged to about 4V without degradation or safety issues. To store more energy it doesn’t make sense to overcharge a LiFePO4 battery.

How to store lithium-ion batteries

Batteries will age, even at storage. In order to extend the lifetime when stored for a longer time, treat the battery as follows:

- Try to keep the battery temperature between 15°C and 25°C.

- Discharge the battery and then charge the battery to 40% of the capacity. For instance, a 10Ah battery should be charged 2 hours at 2A.

Determining the number battery cells

As an example we take the LiFePO4 battery A123 ANR26650.

At 5A the average cell voltage is 3.15V:

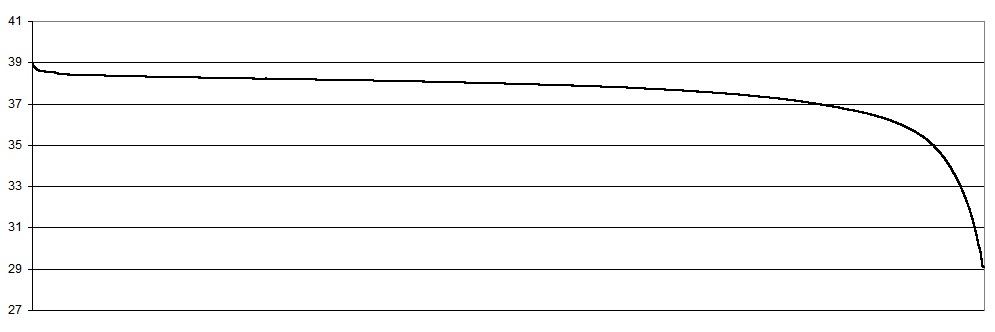

LiFePO4 discharge characteristics

LiFePO4 discharge characteristics

For a motor voltage of 36V the number of cells in series is 12. To get a capacity of for instance 180Wh, we need 24 batteries.

- Configuration:12s2p

- Specification: 39.6V, 4.6Ah, 182Wh

- Weight battery cells: 1.68kg

Battery internal resistance loss

As an example we take the LiFePO4 battery A123 ANR26650.

As we can see below, the internal resistance of the 12s2p battery pack is 110mΩ. Assume the motor input power is 200W:

- I = 200W / 38V = 5.3A

- P battery loss = I² * Ri = 3.1W

- P loss [%] = 3 / 200 = 1.6%

Measuring battery internal resistance

As an example we take the LiFePO4 battery A123 ANR26650.

Battery nickel solder tabs

The A123 solder tabs are not made of copper but of nickel 200/201, which has a high electrical resistivity ρ compared with copper.

- Nickel 200/201: ρ = 9.6 x 10-8 Ω/m

- Copper: ρ = 1.7 x 10-8 Ω/m

The dimensions of the solder tab between two battery cells are 9mm x 0,25mm x 35mm. The resistance is thus 9.6 * 10-8 * 35 * 10-3 / (9 * 10-3 * 0.25 * 10-3) = 1.5mΩ.

Battery DC load test

There's a lot to talk about how to measure the impedance of batteries, if you google on "battery impedance testing" you'll find a lot. Determining the internal battery resistance can be done by using a DC load and measuring the discharge current and voltage drop. The load is simply created with a power MOSFET and three 12V/100W halogen lamps which give a load current of 8.4A

Measuring internal battery resistance

Measuring internal battery resistance

I have connected and disconnected the load several times and measured the battery voltage with a digital storage oscilloscope built with an Arduino.

12s2p LiFePO4 A123 ANR26650 load test 60sec

12s2p LiFePO4 A123 ANR26650 load test 60sec

12s2p LiFePO4 A123 ANR26650 load test 10sec

12s2p LiFePO4 A123 ANR26650 load test 10sec

The negative voltage spikes occurs because the lamps have a positive temperature coefficient. As we can see in the chart, after the voltage jump, the voltage decreases exponentially during more than 60 seconds. Also there is a recovery period after disconnecting the load.

The resistance is measured at the value of the voltage jumps, which average value is ~ 0.8V. This gives a battery pack resistance of 95mΩ (0.8V / 8.4A). It is clear that measuring the rapid voltage jumps with a multi meter is not possible; by the slowness of the measurement we get too large resistance values.

The internal resistance per cell is about 16mΩ which is far more than the value of 10mΩ according to the manufacturer. A123 uses a pulse load test to measure the internal resistance but that gives the AC resistance instead of the DC resistance.

Battery pulse load test

The pulse load is simply created with a 50Hz square wave generator connected to the gate. Use an oscilloscope to measure the battery voltage change.

Battery pulse load measurement

- T battery = 34°C

- VDC = 40V

- I average = 4.95A, I = 9.9A

- Δ Ubat = 0.6V, see scope:

Calculation battery internal resistance

- The battery has 12 cells in series and 2 cells parallel (12s2p)

- The A123 ANR26650 internal resistance = 60.6mΩ / 6 -1.5mΩ = 8.6mΩ

At 25°C the internal resistance is about 10mΩ which is equal to the value in the ANR26650 datasheet. However, this value is too optimistic and practically unusable.

Internal resistance temperature dependence

As the LiFePO4 temperature increases, the internal resistance decreases. See here the results of the measurements that I have done. Note that the chart is measured with the pulse load test.

A123 ANR26650 LiFePO4 internal resistance versus temperature. VDC=40V

A123 ANR26650 LiFePO4 internal resistance versus temperature. VDC=40V

Li-ion, like other battery types, performs better at high temperatures than at low ones. But heat also stresses the battery.

Impedance characteristic temperature dependence

As we see here, the impedance characteristic changes with temperature too.

Battery equivalent electrical circuit

I have created a LiFePO4 cell model that corresponds to the measurements at different temperatures. See more about the so called "randles circuit" here. Please note, it is just a rough approximation and the pulse load test is used.

I still have to make a randles circuit with the DC load test......

A123 ANR26650 LiFePO4 battery simple cell model

A123 ANR26650 LiFePO4 battery simple cell model

Reviving over-discharged Li-ion batteries

One of my Li-ion batteries was fully discharged because a faulty battery fuel gauge pulled constantly 6mA out of the battery, outside of the BMS. Charging was not possible anymore. If the voltage of a one ore more battery cells comes below the cut-off voltage, the BMS comes into action and the battery will be switched off forever. I have done the following to awake the battery back to life:

Open the battery housing. Charge the battery manually with a current of 100mA, outside of the BMS, until the voltage of each cell is higher than the cut-off voltage. This normally just takes less than one minute. The BMS will reset the blockade and charging can be continued in the normal way with the battery charger. The cut-off voltage is 2V to 3V, depending on the battery type. Recovering a single battery cell works the same way. Beware, the procedure is not without risk: if a cell is defective, then the above may result in fire or explosion.

Potential energy

The energy required for climbing hills can be calculated roughly with the potential energy. The motor power loss is not included.

- P [Wh] = m [kg] * g * h / 3600

Eupen – Baraque Michel: E = 90 * 9.81 * 410 / 3600 = 101Wh.

The history of A123

2001: A123 was founded in the USA.

2012, The Chinese Wanxiang Group acquire 80% of A123 after A123 was bankrupted, the name changed to 123 Systems.

2018: Battery manufacturer Lithium Werks in the USA took over 123 Systems from China.

Safe charging and storing lithium-ion batteries

Lithium-ion batteries can catch fire or explode during use and sometimes even when just stored. The safety depends entirely on built in fail-safe circuity electronics.

Charging lithium-ion batteries battery can cause fire. For safety, charge batteries in a fireproof container. But that is not enough, also use fire extinguishing granulate: This is the perfect solution for the safe storage and in the event of a fire, the extinguishing of lithium polymer batteries. When charging, place it over the battery and you have effective and good fire protection. When shipping LiPo batteries, simply pack them neatly around the battery and you don't have to worry anymore.

Safer battery types are LiFePO4, Li-Mn and Lithium-titanate (LT).

Extinguishing granulate

Safety of lithium ion batteries

Comprehensive lithium-ion battery test

Henrik K. Jensen from www.lygte-info.dk has tested many battery cells used for flashlights; these battery cells are used in e-bike batteries too. For instance HERE, 18650 size lithium-ion batteries are tested on capacity:

18650 size lithium-ion battery capacity comparison

18650 size lithium-ion battery capacity comparison

The 18650 size li-ion battery with the highest capacity is the Panasonic NCR18650B (3400mAh).

Battery links

- Fietsaccu-revisie

- Fast Charging Batteries 2025 DESTEN

- Elithion LLC BMS technology, Li-Ion manufacturers etc.

- Batteryuniversity

- Parameterization of a 14.5 Ah LiFePO4-battery cell. Peter Andersson, Olle Collin

- How to rebuild a Li-Ion battery pack

- Tesla Roadster battery technology

Tesla Roadster battery technology

Tesla Roadster battery technology

Other articles from Batteries

Bad e-bike MKEPA batteries cause deadly and devastating fires

- Lipo / LiFePO4 ebike battery information

- E-bike batteries are not allowed on an airplane

- Don’t charge to 100%

- Common battery types for ebikes

- Chemistries

- LiFePO4 batteries

- Other Li-ion batteries

- Hybrid supercapacitor battery

- LiFePO4 battery issues

- How to store lithium-ion batteries

- Determining the number battery cells

- Battery internal resistance loss

- Measuring battery internal resistance

- Reviving over-discharged Li-ion batteries

- The history of A123

- Safe charging and storing lithium-ion batteries

- Comprehensive lithium-ion battery test

- Battery links

- Other articles from Batteries

- Unallowed product tying with e-bike batteries

- Battery fuel gauge discharges e-bike battery

- Building lithium-ion battery pack safety instructions

- Ultra fast charging batteries for e-bikes

- Verboden koppelverkoop bij elektrische fiets accu’s

- Bad e-bike MKEPA batteries cause deadly and devastating fires