Review capacity cell balancing BMS "AE-LMD17 REV A1"

BMS AE-LMD17 REV A1 discharges the battery

I found out that my battery is discharged in a few months by the AE-LMD17 REV A1 BMS, so I can't use it. The battery voltage drops below the lower limit, whereby the BMS disables re-charging. The consume current is measured, it is just 60uA. This low current is not the cause of the discharging; it would take 8 years to discharge the battery. Without the BMS connected, the battery voltage remains constant.

Maybe the battery cell voltages vary among themselves because of temperature changes. This keeps the BMS re-balancing, which discharges the battery.

Capacity cell balancing BMS review

Here, the capacity cell balancing BMS "AE-LMD17 REV A1" is reviewed and tested. Click here for the general article about BMS.

BMS modification

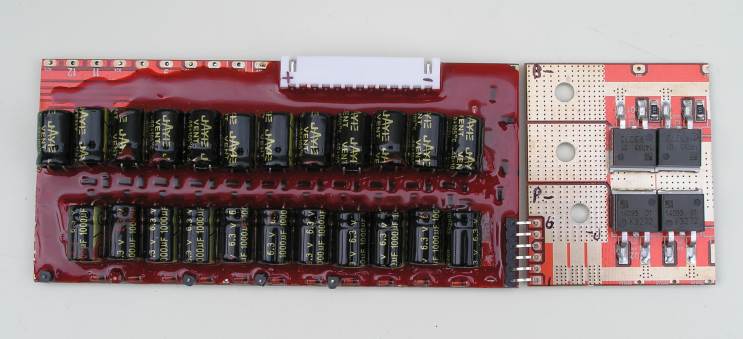

The power MOSFET board is flipped over and shortened:

There are 11 flying capacitors for 12 battery cells.

BMS specifications

- Capacitor cell balancing technique which is working at charging, discharging and static state all the time.

- Battery pack over charge/discharge protection release condition: disconnect load to recover into normal state.

| Battery type | LiFePO4 |

| Single Cell Over Charge Protection Voltage | 3.85V ± 30mV |

| Battery Pack Over Charge Protection Voltage | 43.8V ± 30mV |

| Battery Pack Over Charge Release Voltage | |

| Single Cell Over Discharge Protection Voltage | 2.50V ± 20mV |

| Maximum cell balance current | 2.5A |

| Battery Pack Over Discharge Protection Voltage | 29.4V ± 20mV |

| Maximal Continuous Discharging Current | 60A |

| Maximal Pulse Discharging Current | 80A |

| Maximal Charging Current | 15A |

| Over Discharge Current Protection Detection Current | 100A |

| Over Charge Protection Delay Time | 2s |

| Over Discharge Protection Delay Time | 0.5s |

| Over Discharge Current Protection Delay Time | 50ms |

| Consume Current | 200uA |

| Output impedance | 0.12mΩ |

| The voltage of each cells equalization precision | |

| Dimensions | 108mm x 52mm x 20mm |

| Weight | 108g |

| Working temperature range | -15°C ... 75°C |

BMS wiring diagram

Wiring diagram capacitive battery cell balancing BMS

Wiring diagram capacitive battery cell balancing BMS

BMS power MOSFET circuit

During charging, the current flows into the battery while during load or discharge the current flows in the opposite direction. Therefore, a BMS need two transistors in opposite direction in series:

- Q1 and Q2 are the discharge transistors. During discharging, Q1 and Q2 are in forward mode and can be turned off at battery undervoltage.

- Q3 and Q4 are the charge transistors. During charging, Q3 and Q4 are in forward mode and can be turned off at battery overvoltage.

The other two transistors are always in reverse mode and turned on to avoid the body diode loss.

BMS AE-LMD17 REV A1 reengineered

The BMS electronic is encapsulated. Of course this is an extra challenge to see what's inside. By heating the epoxy it will be soft and can be removed, though with great difficulty.

Unfortunately, the IC markings are gone. Per cell *1) it contains these components:

- 2 IC’s; 14 pin, 8 pin *1)

- 3 power SOT-26 mosfets *1)

- 7 diodes

- About 22 resistors or capacitors

- 8 transistors

- 2 capacitors 1000uF

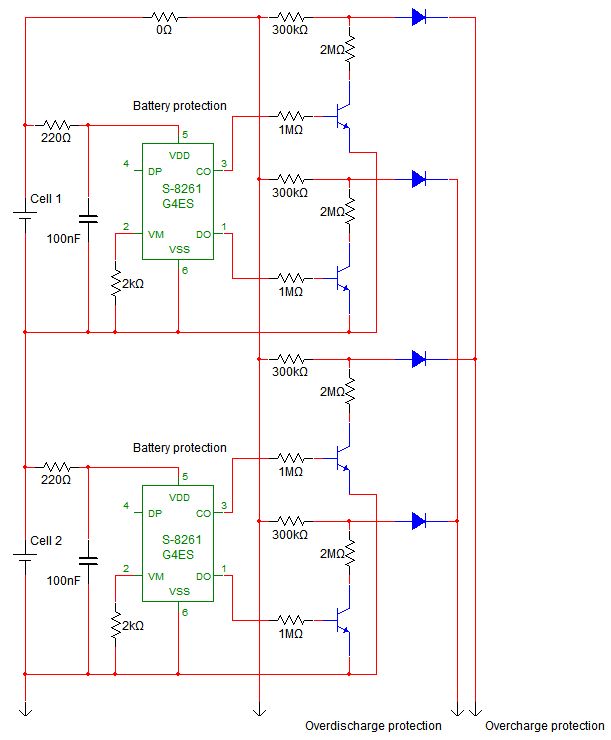

- 1 S-8261 battery voltage protection IC

*1) The cell balance electronics is built around the two IC’s and the three SOT-26 mosfets. It contains 11 similar circuits, not 12!

Together with about 60 parts for the control circuit it contains more than 600 electronic components.

Battery cell voltage protection

The battery voltage protection circuit is reengineered:

BMS battery cell voltage protection

BMS battery cell voltage protection

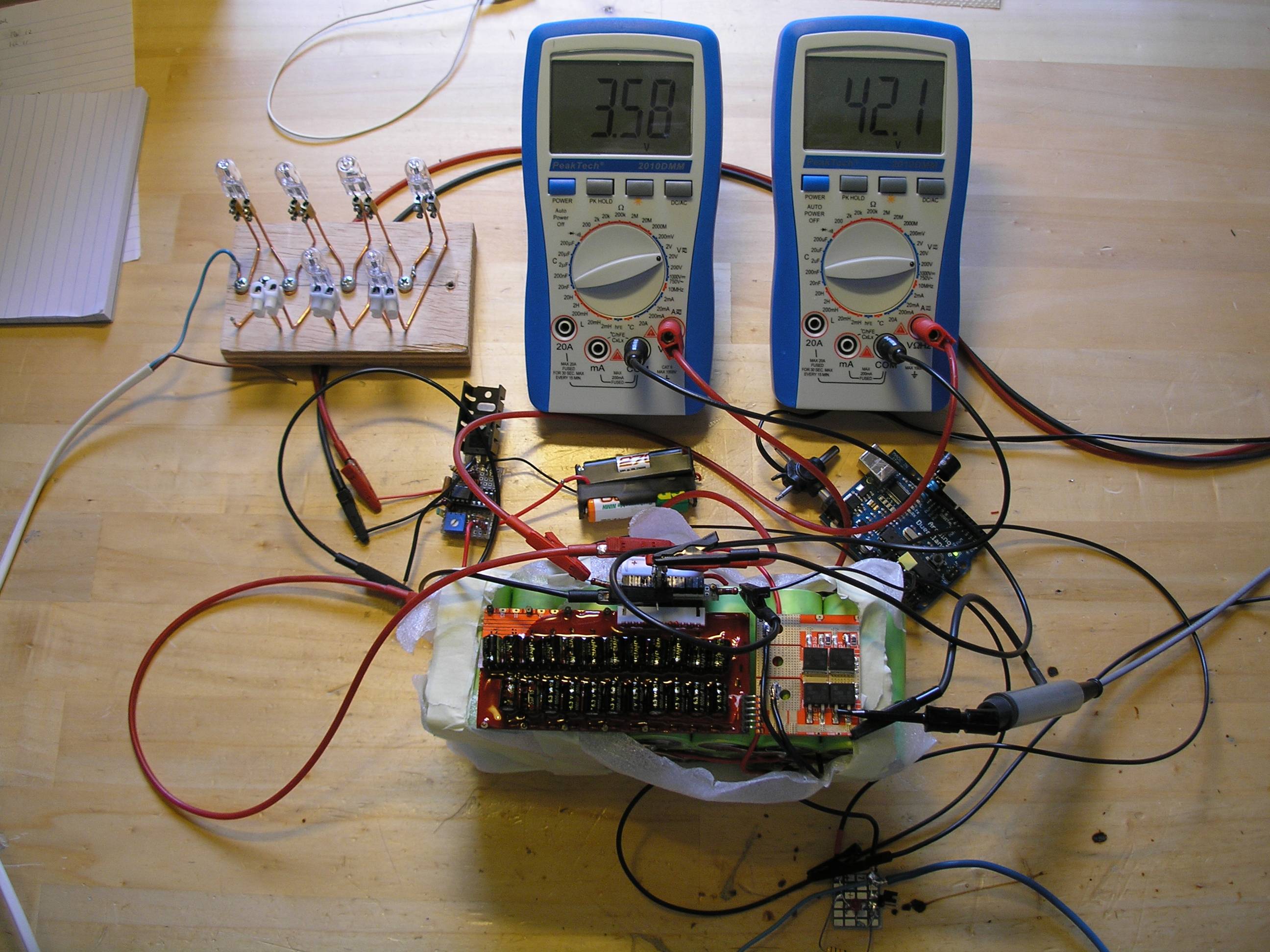

Capacity cell balancing BMS tested

Capacity balancing BMS on the test bench

Capacity balancing BMS on the test bench

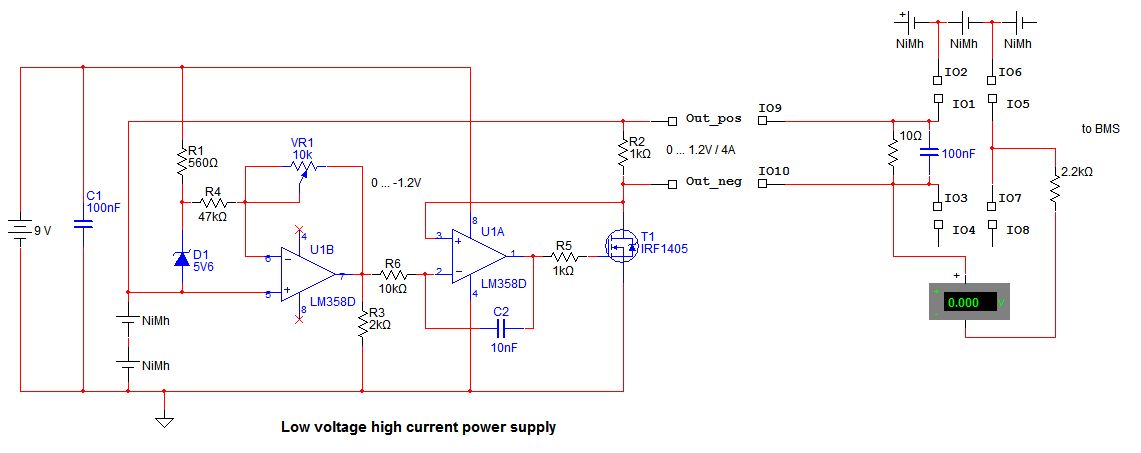

BMS test supply

I had to build a high current / low voltage power supply to test the BMS.

Cell balance circuit

I have measured the cell-balancing current as a function of the LiFePO4 battery cell voltage difference. The balance current can be more than 4A, see the chart. The relationship is 7mA/mV.

Cell balance current versus battery cell voltage difference

Cell balance current versus battery cell voltage difference

The cell balance frequency is 20kHz.

Measured values

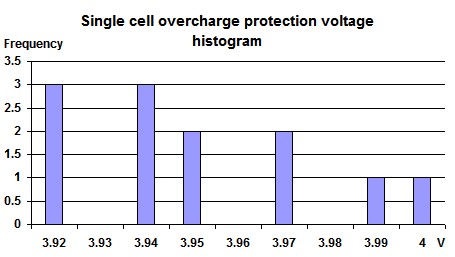

| Single Cell Overcharge Protection Voltage | 3.95V (see histogram) |

| Battery Pack Overcharge Protection Voltage | 44.8V (3.7V/cell) |

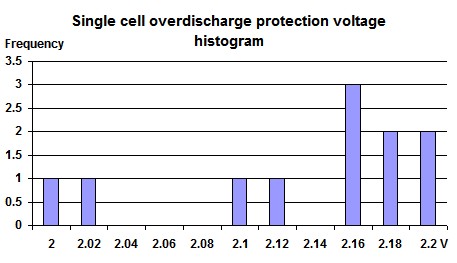

| Single Cell Overdischarge Protection Voltage | 2.15V (see histogram) |

| Battery Pack Overdischarge Protection Voltage | 28.9V (2.4V/cell) |

| Consume Current | 60uA (cell 12) |

A123 26650M1A 12s2p charge graph

To test the battery pack protection, the battery pack is charged with a constant current of 6A, this is 3A per cell. The battery pack overcharge protection voltage is 44.8V, which is outside the specification. The protection voltage is 3.7V per cell, which is higher than the recommended A123 value of 3.6V. At the circle in the graph we see that the charging process is not stopped immediately because the protection voltage is too high. Also the charging process is repeated. At this point, the BMS must be improved.

A123 26650M1A 12s2p charge graph

A123 26650M1A 12s2p charge graph

The battery capacity meets the A123 26650M1A specification; the load time to 3.6V is 2740s. The gross battery capacity = 2740s x 3A = 2.3Ah.

Single cell protection voltage tolerance

For the spreading in the single cell protection voltages, see the histograms:

Bms single cell overcharge protection voltage tolerance

Bms single cell overcharge protection voltage tolerance

Bms single cell overdischarge protection voltage tolerance

Bms single cell overdischarge protection voltage tolerance

Over discharge current protection

I use a 5 x 20mm F16A fuse in series with the battery. Making a short circuit doesn’t blow up the fuse, so the over discharge current protection works fine. But I wonder how the overcurrent protections works, the BMS contains no shunt.

Notes

- The single cell overcharge protection voltage is 3.95V, which is higher than the recommended A123 value of 3.6V.

- The single cell overcharge protection has no fold back.

- The consume current is measured with all battery cells balanced.

- The input current of the remaining 11 cells was less than 20uA each.

- The individual battery cell voltages are most different just after the battery is charged. It is obvious that cell balancing work best if we take a rest after after charging.