Bosch Active Line 3 mid-drive motor tear down

- Bosch Active Line 3 facts

- Attention: hollow shaft position

- Putty thermal gap fillers

- Replacing the thermal gap filler pads

- Comparison with the Bosch Performance Line CX

- Bosch Active Line 3 freewheel

- Magnetostrictive torque sensor of the Bosch Active Line

- Bosch Active Line 3 gear design

- Lubrication

- Bosch Active Line 3 motor curve

- Friction torque Tf

- Motor construction

- Bosch motor graphs

- Permanently sticky glue

- Forums

- Part 2

For my solar powered bicycle, the Maxun One, I designed a very powerful and lightweight mid-drive motor. I also wanted to investigate whether I could use a Bosch Active Line 3 motor. The Bosch motor weight is 2975g, this is relatively lightweight for a mid-drive motor, but it is still too heavy for my solar bike.

So, I wanted to investigate if the Bosch motor can be reduced in weight, so I disassembled the motor. This is also a great opportunity to see how it works and which electronic parts are used.

See also part 2 Bosch Active Line 3 printed circuit board expained

Bosch active line 3 disassembly

Bosch active line 3 disassembly

Bosch active line 3 typenumber

Bosch active line 3 typenumber

Bosch Active Line 3 facts

- On the market since end 2017

- Max. 250W / 40Nm

- Max. cadence 100rpm

- Weight 2975g without plastic covers, metal holder and bolts

- Weight 3345g with plastic covers, metal holder and bolts

What is striking after opening the motor is that there are only a few parts inside, that is a great achievement of the Bosch engineers:

Bosch Active Line 3 mid-drive motor dismantled

Bosch Active Line 3 mid-drive motor dismantled

Bosch Active Line 3 mid-drive motor inside

Bosch Active Line 3 mid-drive motor inside

Bosch Active Line 3 mid-drive motor taken apart

Bosch Active Line 3 mid-drive motor taken apart

Attention: hollow shaft position

The position of the hollow shaft (119g) relative to the bottom bracket (243g) may not be changed. Mark the position before dismantling. Otherwise you may get a 510 internal sensor error.

Putty thermal gap fillers

In mid-drive motors, often putty thermal gap fillers are used. These are not elastic and must be replaced when the PCB is replaced. They cannot rebound to the original shape after pressure is removed. At four places of the PCB, semiconductors are cooled to the the aluminum housing via the thermal pads.

Replace the gap filling thermal conductive material after repair

Replace the gap filling thermal conductive material after repair

Bosch has used a blue putty thermal gap filler, this was completely dried up and had become brittle. You can see this on this video:

Replacing the thermal gap filler pads

I have looked if there are thermal pads which do not always have to be replaced after repairing the motor. The thermal pad must be elastic and has to rebound to the original shape after the pressure is removed. The Bergquist Gap Pad TGP 1000VOUS meets these requirements. The viscoelastic nature of the material also gives excellent low-stress vibration dampening and shock absorbing characteristics. The required thickness is 1mm for both the Bosch and Yamaha mid-drive motors. The thermal conductivity is 1 W/mK with 1mm.

Here is a nice video about thermal pads:

Comparison with the Bosch Performance Line CX

The Bosch Active Line 3 is a simple budget motor, with only one gearset and therefore limited power. The Performace line CX is much better in design and weighs also just 2.9 kg. This motor is therefore used on the expensive e-mountain bikes. Here we can see that the Bosch Performance Line CX is much more complex than the Active line 3, it has two gears, one for the motor and one for the bottom bracket:

Bosch Performance Line CX inside view

Bosch Performance Line CX inside view

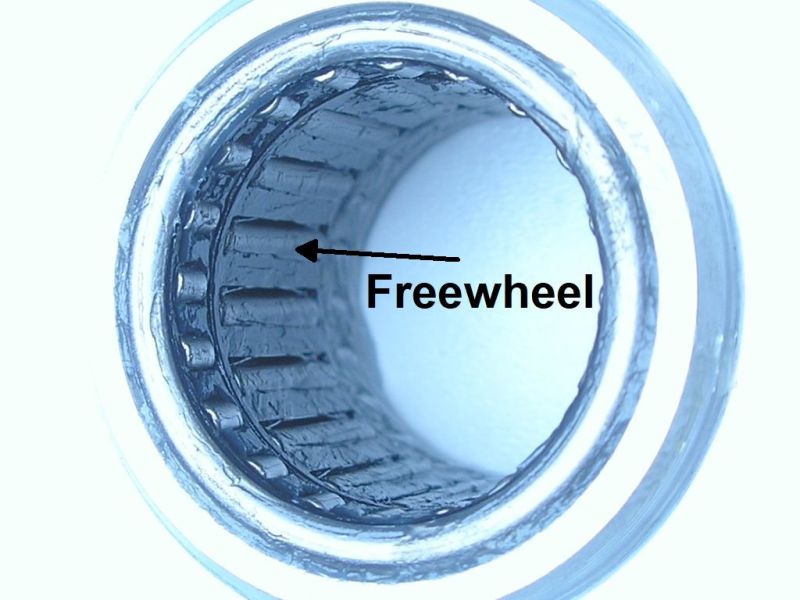

Bosch Active Line 3 freewheel

The motor has just one freewheel, used for pedaling without turning the motor. But the motor can’t drive the rear wheel without the pedals turning, this requires an extra freewheel.

Bosch active line 3 freewheel

Bosch active line 3 freewheel Freewheel

Freewheel

Magnetostrictive torque sensor of the Bosch Active Line

Bosch active line 3 torque sensor

Bosch active line 3 torque sensor

Torque sensor plain bearing

Torque sensor plain bearing Torque sensor plain bearing

Torque sensor plain bearing

The torque is measured on an extra hollow shaft, which will twist as a result of the torque. This torque is measured magnetically by coils using the inverse magnetostrictive effect.

See more about torque sensors HERE.

Bosch Active Line 3 gear design

The motor must have a speed above 1000 rpm, otherwise the motor losses will be too high, see the article motor tuning. So, we always need a gear. The previous Bosch mid drive motors have four gears wheels, but the Bosch Active Line 3 has just two gear wheels. That limits the transmission ratio, and so the motor efficiency, unless we take a motor gear wheel with very few teeth. To avoid gear undercutting, the minimum number of teeth of a gear is commonly 12, but that is too much in our situation. The reason that Bosch uses a helical gear is not just noise reduction, more important is that helical gears allows a low number of teeth without undercutting.

The motor gear has just 5 teeth, which is very rare.

Bosch active line 3 motor gear wheel

Bosch active line 3 motor gear wheel

The large gear is made of nylon:

- Teeth number 71

- Diameter 115mm

- Width 18.5mm

- Helix angle 15º

- Module m = 112mm / 71 = 1.6

Note that the gear wheel is not standard: https://nl.wikipedia.org/wiki/Modulus_(tandwielen).

The gear ratio is 71 / 5 = 14.2. At a cadence of 100rpm, the motor speed is 1420 rpm which is quite low. But with just two gear wheels, the mechanic loss is low and that partially compensates for the poor motor efficiency caused by the low motor speed.

Lubrication

It is remarkable that the gears are nearby the PCB but the electronics remain free of grease. The grease is apparently not being thrown around. This requires a special grease with a certain thickness. Used is “Renolit WTF 2B Bosch Drive Unit Fett”. The small motor gear is fitted with a plastic cap, which ensures that the grease stays on the gear wheels. The nylon plate between the large gear and the cover has the same purpose.

The Renolit WTF 2B is not available in small quantities. There is also another grease that can be used: Molykote EM 30L and this is available in a 50mL tube.

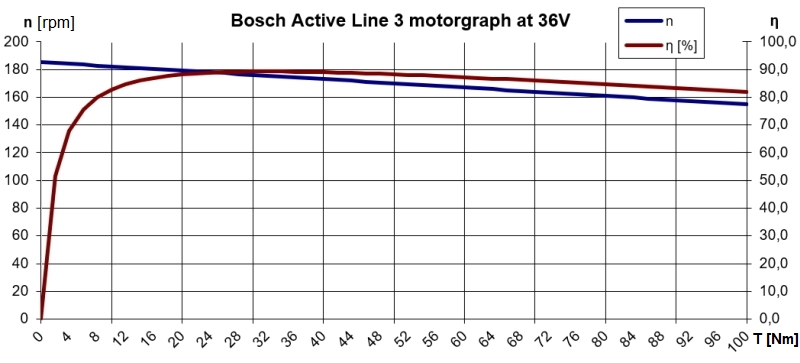

Bosch Active Line 3 motor curve

Just 3 motor parameters are required to create the motor curve: R, k and Tf. These will be measured and calulated here.

Motor resistance R

This is the resistance between two motor terminals:

R = 0.109Ω

Motor constant k

The motor constant k is measured with an external motorcontroller KU63 at a voltage of 36V, which is directly connected to the motor, see here:

Here, the motor constant k relates to the motor-gearbox combination. The voltage, no load current and speed at the output axis are measured, fortuitous it are round numbers:

- U = 38.7V

- I= 1.00A

- rpm = 200

Calculation of k:

- k = U / ω = U * 60 / ( 2 * Π * rpm)

- k = 1.85

Friction torque Tf

- Tf = I0 * k

- Tf = 1.85

Motor construction

- Stator 18 pole

- Rotor 14 pole

- Rotor diameter 46mm

- Rotor length 46mm

- Stator outer diameter 84mm

- Gear ratio 14.2

Bosch motor graphs

You can download the Excel sheet that is used at GitHub here.

Bosch Active Line motor graph at 36V

Bosch Active Line motor graph at 36V

We see that the speed at 36V is very high: 185 rpm, nobody cycles with a cadence of 185 rpm. This means that the motor runs internally at a lower voltage. The maximum cadence according to Bosch is 100 rpm, but we will take 120rpm. A cadence of 120rpm corresponds to a motor voltage of 24V. A new motor graph is therefore calculated at 24V instead of 36V:

Bosch Active Line motorgraph 24V

Bosch Active Line motorgraph 24V

The Bosch motor has only two gear wheels, which cause less loss. Including an assumed gear loss of 5%, we get the following graph:

Bosch Active Line motorgraph 24V with gear loss

Bosch Active Line motorgraph 24V with gear loss

Normally, the duty cycle of a PWM motor control is 0% for 0V and 100% for 36V. However, at the Bosch Active Line 3, the maximum duty cycle is 24V/36V = 67%. We can also say that the internal motor is a 24V motor. It is not clear why Bosch uses a 24V instead of 36V motor. This reduces the efficiency of the motor controller because the maximum current is greater and therefore the losses in the Mosfets as well.

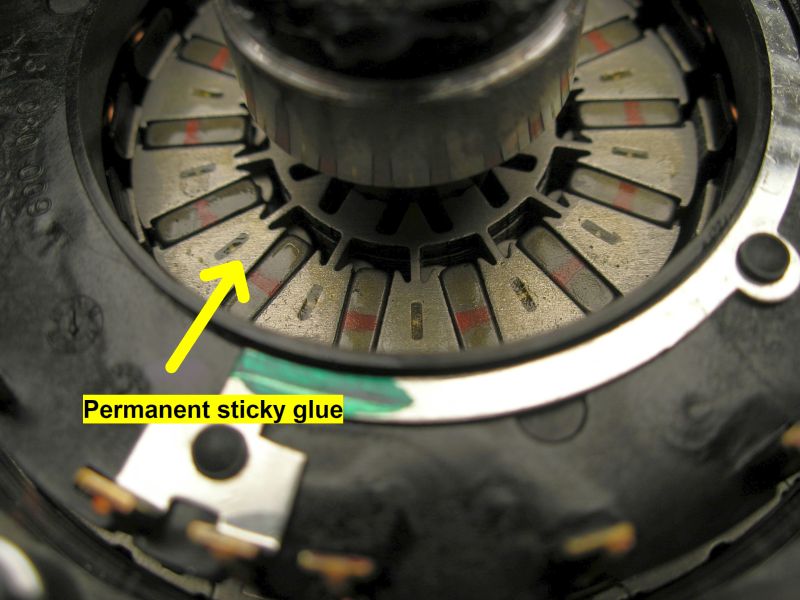

Permanently sticky glue

Note that there is some permanently sticky glue on the rotor. I suppose, this attracts dirt particles to prevent them from entering the motor.

Permanent sticky glue Bosch Active Line 3 motor

Permanent sticky glue Bosch Active Line 3 motor

Forums

https://endless-sphere.com/forums/viewtopic.php?f=30&t=96269

https://www.pedelecforum.de/forum/index.php?threads/active-line-3-plus-mj-2018-bdu-310-350-infos-innenleben.58208/

Part 2

Bosch Active Line 3 printed circuit board dismantled

Bosch active line 3 PCB explained

Bosch active line 3 PCB explained