Review Xiongda dual-speed hub motor

- Related articles

- Which motor is best suited for building a lightweight 250W e-bike?

- Properties of the lightweight Maxun e-bike.

- Throttle control instead of torque control

- Don’t use a derailleur on an ebike

- 250W e-bike motors compared

- Dual-speed hub motor

- The final motor selection

- Mid drive motor

- Hub motor

- The winner is the Xiongda 2-speed hub motor

- Disc brakes can’t be used

- Things to be done

- Summary

- Xiongda 2-speed motor tear-down

- Xiongda 2-speed motor weight saving

- Links

Related articles

- E-bike motors 250W compared by simulation: mid-drive vs hub vs 2-speed hub

- E-bike mid-drive motors compared

- Simulation e-bike hub / mid-drive motor efficiency vs speed

Note: this article only applies to e-bikes up to 250W

Which motor is best suited for building a lightweight 250W e-bike?

I want to build some lightweight e-bikes and I've figured out which motor is best suited to achieve this. The ebike will also be used for the revolutionary Maxun One solar bike. In this article, I want to share my research work. In this technical article, I conduct a comprehensive performance analysis of the Xiongda 2-speed motor and compare it to both 250W hub motors and mid-drive motors. My extensive simulations and testing confirm that the Xiongda motor performs just as well as mid-drive motors that are considerably more expensive.

Properties of the lightweight Maxun e-bike.

- Total weight less than 14kg

- Must be strong uphill

- 250W motor

- Lightweight 1750g carbon gravel frame

- Zero cadence support

- Lightweight hollow ISIS bottom bracket

- Shimano Alfine hub gear

Throttle control instead of torque control

Mid drive motors use a torque sensor together with software to provide a natural cycling feeling, which many people like. But I prefer a throttle only because when driving on my solar bike, the Maxun One, I don't have to pedal at all most of the time.

Don’t use a derailleur on an ebike

I’m a big opponent of derailleur gears on ebikes. Only road bikes need a derailleur because of the low mechanical losses. But for an e-bike this doesn't matter. Because a hub gear is maintenance-friendly it is much better choice for an ebike. The only disadvantage is that with using a hub gear it is not possible anymore to use a hub motor in the rear wheel.

250W e-bike motors compared

Now, we are going to look at the pros and cons of the following ebike motors:

- Front hub motor

- Dual-speed front hub motor

- Mid drive motor

Front wheel hub motor

Front wheel hub motor Xiongda 2-speed front wheel hub motor

Xiongda 2-speed front wheel hub motor Mid-drive motor

Mid-drive motor

Hub motor

Pros

- Low weight (for example 1.76kg for the 250W Cute Q-85SX)

- Low price

- Low pedaling resistance when cycling without motor support

- The hub gear can’t be overloaded by the motor

- No special frame is needed

- Due to the use of a planetary gear transmission, the motor is robust

Cons

- Very poor efficiency uphill

Dual-speed hub motor

Note that Xiongda is the only manufacturer.

Xiongda 2-speed hub motor 3.2kg

Xiongda 2-speed hub motor 3.2kg

Pros

- It has all the advantages of a hub motor

- Uphill performs is almost the same as a mid-drive motor, see the simulations

- Low price

Cons

- Quite high weight of 3.2kg

- The motor power is actually 350W, which is in principle higher than the legal limit of 250W for Pedelecs in Europe.

Mid drive motor

Pros

- Very good performance uphill

Cons

- The hub gear may be overloaded by the motor

- Usually, a special (heavy) frame is required

- Most mid drive motors are not for sale separately for private persons

- Mid drive motors break down quite often and since repairs are mostly not possible, replacing is much more expensive than a hub motor.

- There is serious pedaling resistance when you ride without motor assistance, this is because the freewheel is not mounted directly on the crankshaft, which would be best, but inside the motor, behind one or more gearwheels. This causes the extra friction.

See this article E-bike mid-drive motors compared: Bosch vs Shimano, Panasonic, Yamaha, Brose, Polini, Bafang, Tongsheng

Things to know about hub motors

It is important to know that, from an electromechanical viewpoint, all 250W well-built mid-drive motors have more or less the same efficiency characteristics. That is because all use the same motor type: a permanent magnetic motor.

To get high efficiency, a permanent magnetic motor must have a high speed, see this article: Permanent magnet DC electric motor tuning

When driving uphill, the speed is low but the required power is high. A hub motor has a low-speed uphill and that is why the efficiency is very bad here. The speed of a mid-drive motor is constant at all cycling speeds, that's why a mid-drive motor performs better.

The final motor selection

Mid drive motor

I want to use a standard carbon frame because is low weight. Therefore, the mid-drive motor has to be mounted on a common bottom bracket.

There are only two motor available: the Tongsheng TSDZ2 and the Bafang BBS02

Tongsheng TSDZ2

Tongsheng TSDZ2 Bafang BBSO2

Bafang BBSO2

However, these motors have some serious drawbacks:

- The crank distance is increased

- Heavy weight

- No possibility to use a lightweight ISIS axis.

- I find them ugly

Hub motor

I have a lot of experience with the Cute Q-85SX hub motor, which is used on my Maxun One solarbike. The motor is, lightweight (1.76kg), cheap and very durable. The only problem is that the motor has a low efficiency uphill, which causes high losses. To overcome this, you always have to pedal too uphill. If only the lowest weight is the main argument, then a hub motor is the best choice. But since the ebike needs to be powerful uphill, I can't use a normal hub motor.

The winner is the Xiongda 2-speed hub motor

When considering the pros and cons of all motors, the Xiongda 2-speed hub motor comes out on top. Extensive simulations have shown that it performs as well as a 250W mid drive motor. The weight of 3.2kg is quite high, but this can be compensated with using a lightweight hollow ISIS bottom bracket, which is not possible with the mid drive motors TSDZ2 and BBS02.

Disc brakes can’t be used

A nice-looking bicycle needs a carbon frame and a carbon front fork too. The dropout distance of a front fork is standard 100mm. But the 100mm wide Xiongda 2-speed motor is made for v-brakes only, while disc brakes are the standard nowadays. Xiongda has a disc brake version of the 2-speed motor but this is unusable because its dropout is 110mm and such front forks don’t exist in carbon.

Things to be done

- For the Xiongda 2-speed motor, I want to have a special carbon fork fabricated with strong dropouts, so that no torque arm is needed anymore.

- The corresponding 2-speed motor controller has to be modified for obtaining motor current control.

Summary

The Xiongda 2-speed hub motor allows me to build a very lightweight ebike. Any common carbon frame can be used which makes the ebike nice looking. As the simulations shows, the motor has almost as good uphill performance as a mid-drive motor.

With a standard 100mm carbon front fork, no disc brake is possible, but this is actually not a big disadvantage, I can live with this.

Xiongda 2-speed is almost as good uphill as a mid-drive motor

Xiongda 2-speed is almost as good uphill as a mid-drive motor

Xiongda 2-speed motor tear-down

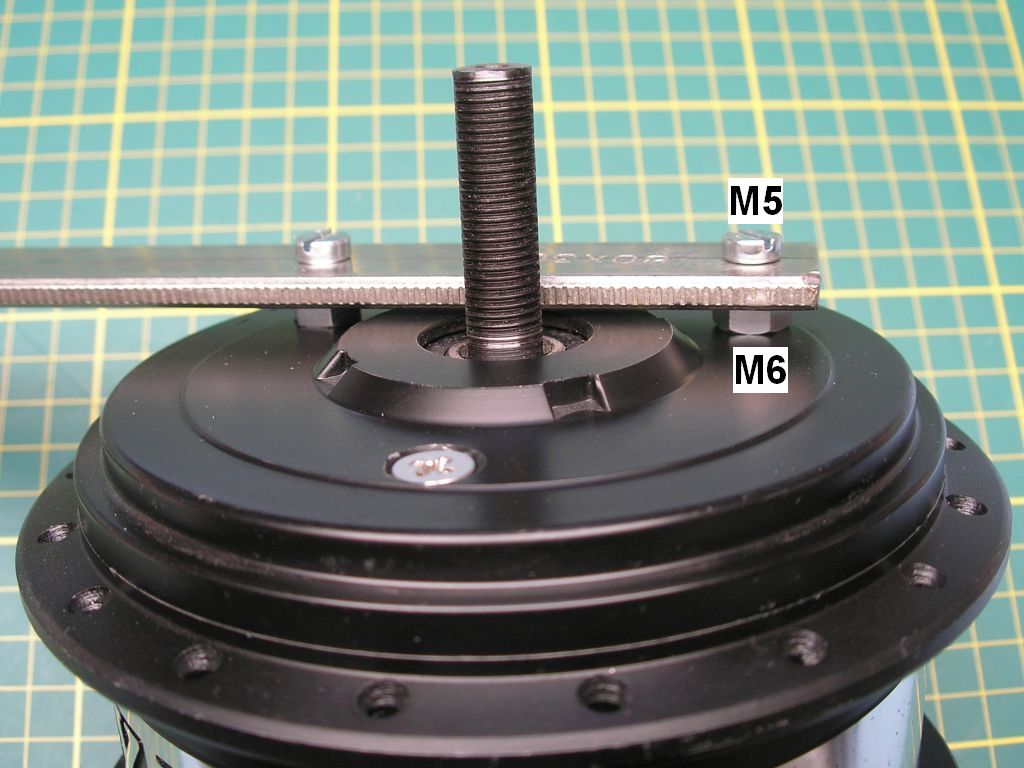

Xiongda 2 speed motor unscrew

Xiongda 2 speed motor unscrew

Xiongda 2 speed motor

Xiongda 2 speed motor Xiongda 2-speed housing

Xiongda 2-speed housing

Xiongda BLCD 2-speed motor high fill factor

Xiongda BLCD 2-speed motor high fill factor Xiongda 2-speed motor Hall sensors

Xiongda 2-speed motor Hall sensors

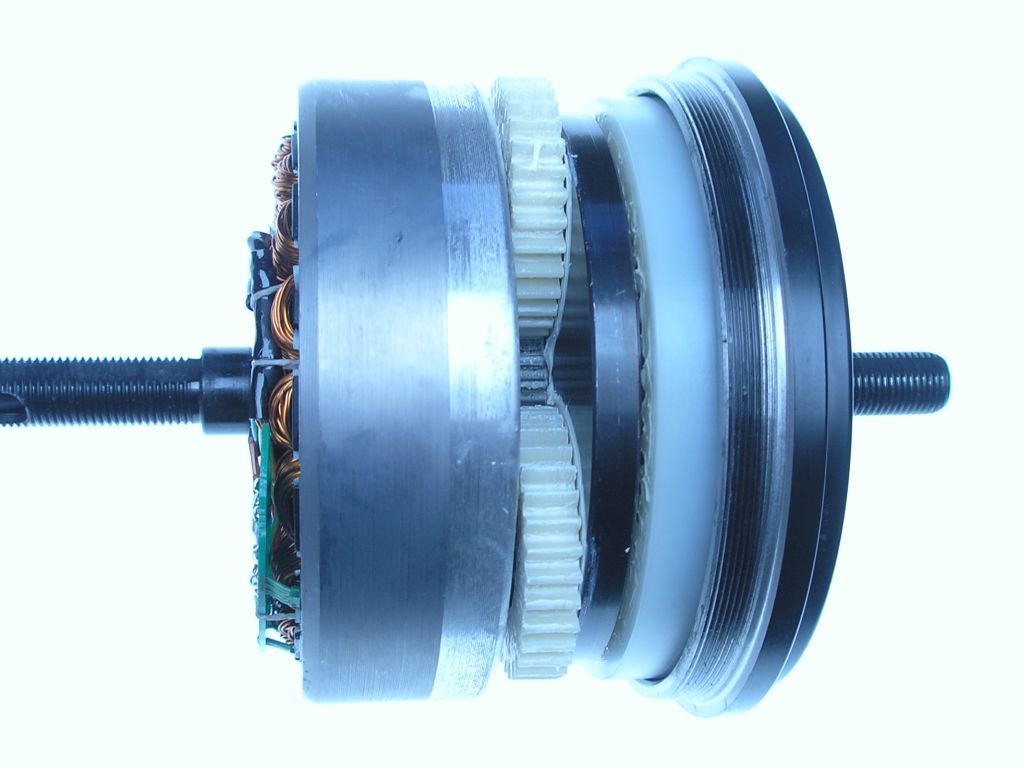

Xiongda 2-speed motor tear-down

Xiongda 2-speed motor tear-down

It is remarkable that the Xiongda 2-speed motor has a fill factor of almost 100%, not a single winding can be added anymore. That significantly increases the motor's efficiency.

Xiongda 2-speed motor weight saving

The motor is with 3.2kg very heavy. I think, it is possible to reduce the weight. Some parts are made of steel and may be replaced by aluminum or titanium.

For example, the black plate between the two planetary gears is now made of steel. The diameter and thickness are resp. 94mm and 7mm. In steel, this part weighs about 350g and in aluminum 125g. That already gives a saving of 225g. If we continue in this way, perhaps more than 500g can be saved and the motor will weigh less than 2.7kg.